Series TA-FTSW (Straight-way)

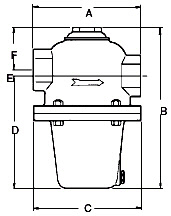

| Dimension Table | ||||||||

| Trap No. |

Tapping In. |

Weight Lbs. |

Dimensions | |||||

| A | B | C | D | E | F | |||

| FTSW3 | 3/4 | 6 | 4-1/2 | 6-1/2 | 4-1/2 | 4-5/16 | 5/16 | 1-7/8 |

| FTSW4 | 1 | 9 | 5-1/2 | 7-7/8 | 5-1/2 | 5-5/8 | 3/16 | 2-1/16 |

| FTSW5 | 1-1/4 | 12 | 5-1/2 | 8 | 6 | 5-1/2 | 1/2 | 2 |

| FTSW6 | 1-1/2 | 37 | 7-5/8 | 11-3/4 | 8-9/16 | 9-1/16 | 1/2 | 2-3/16 |

| FTSW8 | 2 | 59 | 9-5/16 | 13-13/16 | 10-3/8 | 10-15/16 | 1/2 | 2-3/8 |

| Capacity Table – 15 psi Traps | |||||||||

| Trap Ordering Number |

Capacity-Pounds per Hour* | ||||||||

| Pressure Difference – Lbs. per Sq. In. | |||||||||

| 1/8 | 1/4 | 1/2 | 3/4 | 1 | 2 | 5 | 10 | 15 | |

| FTSW3 | 50 | 70 | 100 | 120 | 140 | 200 | 210 | 220 | 230 |

| FTSW4 | 125 | 175 | 250 | 300 | 350 | 500 | 525 | 550 | 575 |

| FTSW5 | 300 | 425 | 600 | 735 | 850 | 1200 | 1260 | 1320 | 1380 |

| FTSW6 | 600 | 850 | 1200 | 1470 | 1700 | 2400 | 2520 | 2640 | 2760 |

| FTSW8 | 1250 | 1775 | 2500 | 3060 | 3550 | 5000 | 5250 | 5500 | 5750 |

*Capacities according to recommended SHEMA standards.

| Capacity Table – 30 & 50 psi Traps | |||||||||||||||

| Ordering No. | Orifice | Capacity pounds per Hour – Continuous Discharge.** | |||||||||||||

| Trap No. |

Max. Pres. |

No. |

Dia. |

Pressure Difference – PSI | |||||||||||

| 1/8 | 1/4 | 1/2 | 1 | 2 | 5 | 10 | 15 | 20 | 30 | 40 | 50 | ||||

| FTSW3 | 50 | S | 3/32 | 39 | 52 | 69 | 92 | 122 | 180 | 240 | 285 | 320 | 380 | 430 | 470 |

| FTSW4 | 30 50 |

D E |

1/8 7/64 |

71 60 |

95 81 |

127 108 |

170 243 |

228 190 |

335 280 |

445 375 |

530 440 |

600 500 |

700 590 |

– 670 |

– 730 |

| FTSW5 | 30 50 |

C D |

5/32 1/8 |

118 75 |

156 102 |

210 138 |

280 182 |

375 245 |

550 355 |

740 475 |

870 565 |

980 630 |

1160 750 |

– 840 |

– 920 |

| FTSW6 | 30 50 |

91-30 91-50 |

19/64 15/64 |

390 270 |

525 360 |

700 480 |

940 640 |

1250 860 |

1850 1260 |

2450 1680 |

2930 2000 |

3300 2250 |

3900 2670 |

– 3000 |

– 3300 |

| FTSW8 | 30 50 |

101-30 101-50 |

11/32 9/32 |

500 345 |

670 460 |

890 610 |

1180 820 |

1580 1100 |

2340 1600 |

3120 2140 |

3700 2520 |

4150 2840 |

4900 3350 |

– 3800 |

– 4150 |

**Capacities based on FCI 65-3 standard for determing industrial steam trap capacity rating.

| Materials of Construction: | |

| Body and Cover – Cast Iron (125 psi Class) | Condensate Valve and Seat – Hardened #416 Stainless |

| Thermal Element Cover – Forged Brass | Valve Stems – #416 Stainless |

| Thermal Element – Phosphor Bronze with #416 Stainless Valve | Discharge Tubes – Brass |

| Thermal Element Seat – #416 Stainless | Valve Stem Guide – Sizes 3, 4 and 5, Brass; 6 and 8, Cast Iron |

| Float – Seamless Copper | |

BULLETIN: Series-TA-FTSW-0814 – Float & Thermostatic Steam Traps – Series TA-FTSW (Straight-Way)