About Tunstall Capsule Steam Traps

Overview

Tunstall Steam Capsules have been in service since 1985. Their warranty performance since that time has resulted in a practically nonexistent failure rate. The Tunstall Steam Trap Capsule has changed the nature of the steam trap repair business.

Tunstall Steam Capsules have been in service since 1985. Their warranty performance since that time has resulted in a practically nonexistent failure rate. The Tunstall Steam Trap Capsule has changed the nature of the steam trap repair business.

Before the advent of stainless steel forming and TIG welding technology, steam traps consisted of thermostatic parts made by crimping and soldering of plated materials; the chief feature of this system resulted in products that had built in obsolescence. Hydro formed phosphor bronze bellows were more successful but the cost was considerably higher than common diaphragm cage assemblies.

Tunstall Steam Trap Capsules are fabricated of TIG welded stainless steel, which take advantage of existing Aerospace Technology, with extremely close manufacturing tolerances. Their stainless steel bellows counterparts can be found on commercial aircraft and aerospace equipment throughout the world.

Tunstall Steam Capsules retrofit almost all thermostatic steam traps made in the early 20th century to the present. Each capsule is individually tested and calibrated before shipment. We believe Tunstall Steam Trap Capsules are by far the best way to repair and upgrade existing traps for years of trouble free service.

We will be glad to manufacture steam trap interiors for any thermostatic trap assembly ever made. Our products provide the simplest, most effective installation and removal process in the business. We warranty all materials and take pride in being the best product available today.

Specifications

Typical Examples

More Information

Fuel Savings Formula

Is a steam trap survey necessary?

1. It takes approximately one lb of steam to generate 1,000 BTU’s.

2. The energy content of one gallon of #6 fuel oil = 149,700 BTU’s with a combustion efficiency of 86.1%

(U.S. Dept. of Energy, Office of Industrial Technologies).

3. With #6 oil at $1.30/gallon then:

1.30 ($/gallon) / 149,700 (BTU/gallon) X 1000 (BTU/lb) X .861 (efficiency) = $.0075 per lb

Therefore the cost of steam is $0.0075/lb or $7.50/1000 lbs

4. Steam trap hours of use per year:

heat season (120 days) X 12 hours per day = 1440 Hours

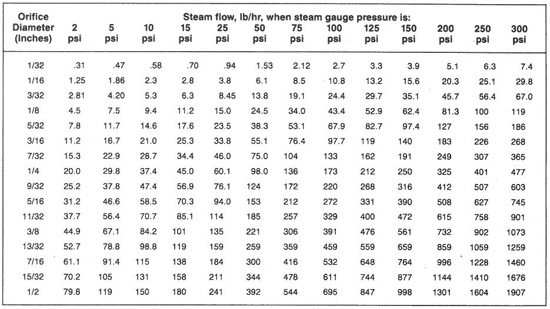

5. Steam loss thru a typical thermostatic trap with a 0.312” (5/16”) orifice at 5 psi (+ 14.7 psi atmospheric pressure) and 50% blocked (based on a variant of the Napier formula, as follows) = 23.3 lbs/hr

Steam flow (to atmosphere) in lbs/hr:

24.24 X pressure psi absolute X diameter of orifice squared X 50% Blockage

24.24 X (5 psi + 14.7 psi) X (.312)(.312) X .50 = 23.3 lbs/hr

6. Therefore, in one heating season, one trap 50% blocked translates into an effective steam loss cost of approximately $250.00 per trap.

steam loss/hr X heating season X cost of steam per lb = cost per season per trap

23.3 lbs/hr X 1440 hrs X $0.0075 per lb = $250 per season per trap

Yes, a Steam Trap survey is necessary! It does pay to inspect, repair, or replace your steam traps!